With UHPC,

Ultra-High Performance Concrete,

Combining fiberglass and using steel molds,

We minimize the pores and micro-cracks inside the material,

Create modules that have high performance and extraordinary visual.

The strength of UHPC can reach 8-10 times that of ordinary concrete.

Our Architectural Concrete modules excel in density, strength, toughness,

making them extremely versatile.

From floor to wall,

They do them all.

Unlike general cement, the high density of UHPC

Gives our Architectural Concrete modules

That smooth surface while retaining the fine, raw texture of concrete

When you touch it,

You feel it.

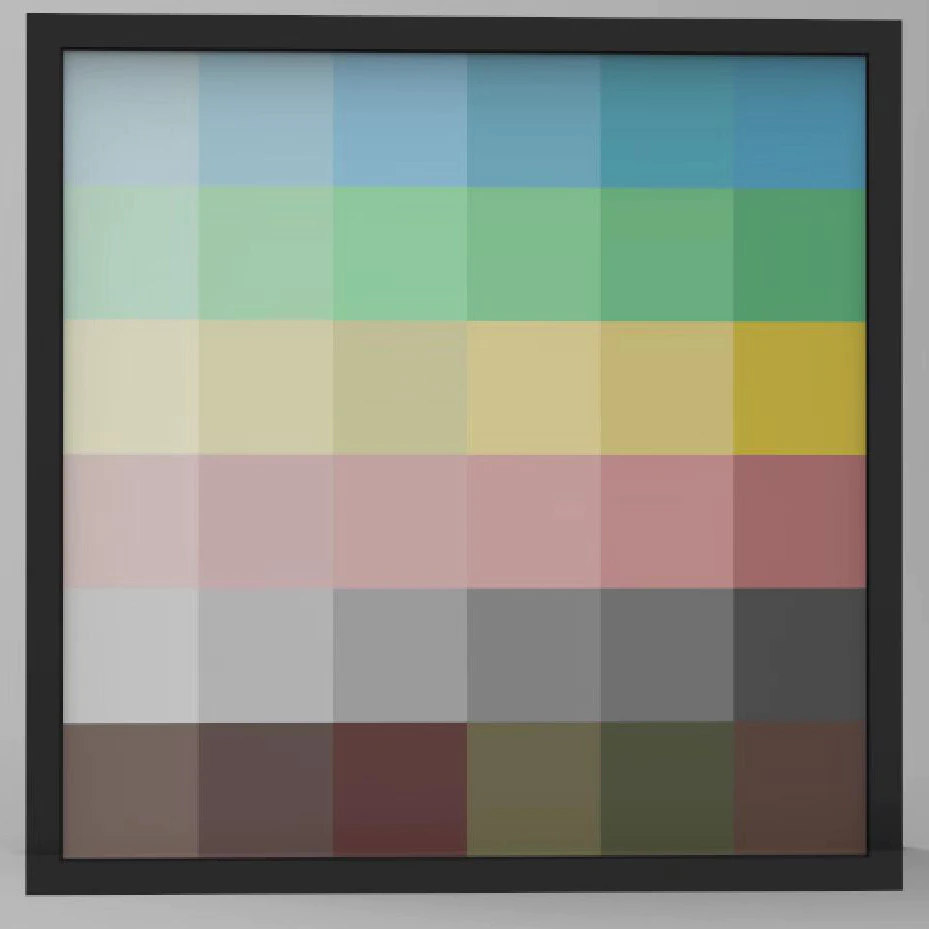

If you see beyond the gray,

Then customise the modules to your wish.

Colours and shapes,

And every detail. Your modules, your way.

** MOQs apply to customisation products.

Traditional concrete is relatively rough, and has lower density and toughness. UHPC has high density, with means smoother surface and fine texture.In addition,the high density also makes our Architectural Concrete modules much easier to maintain.

Architectural Concrete modules made of UHPC have high toughness and strength. Modules are very flexible in use, and can be combined to form a stable and aesthetic structure.

For concrete plates, you might use them on wall and floor. For wall, the minimal thinness is 8mm. As for floor, the minimal thinness is 12mm.

With modular bricks, you can use them to build walls, which serve feature wall and layout of different areas.

The modules are versatile and you might use them as you see fit.